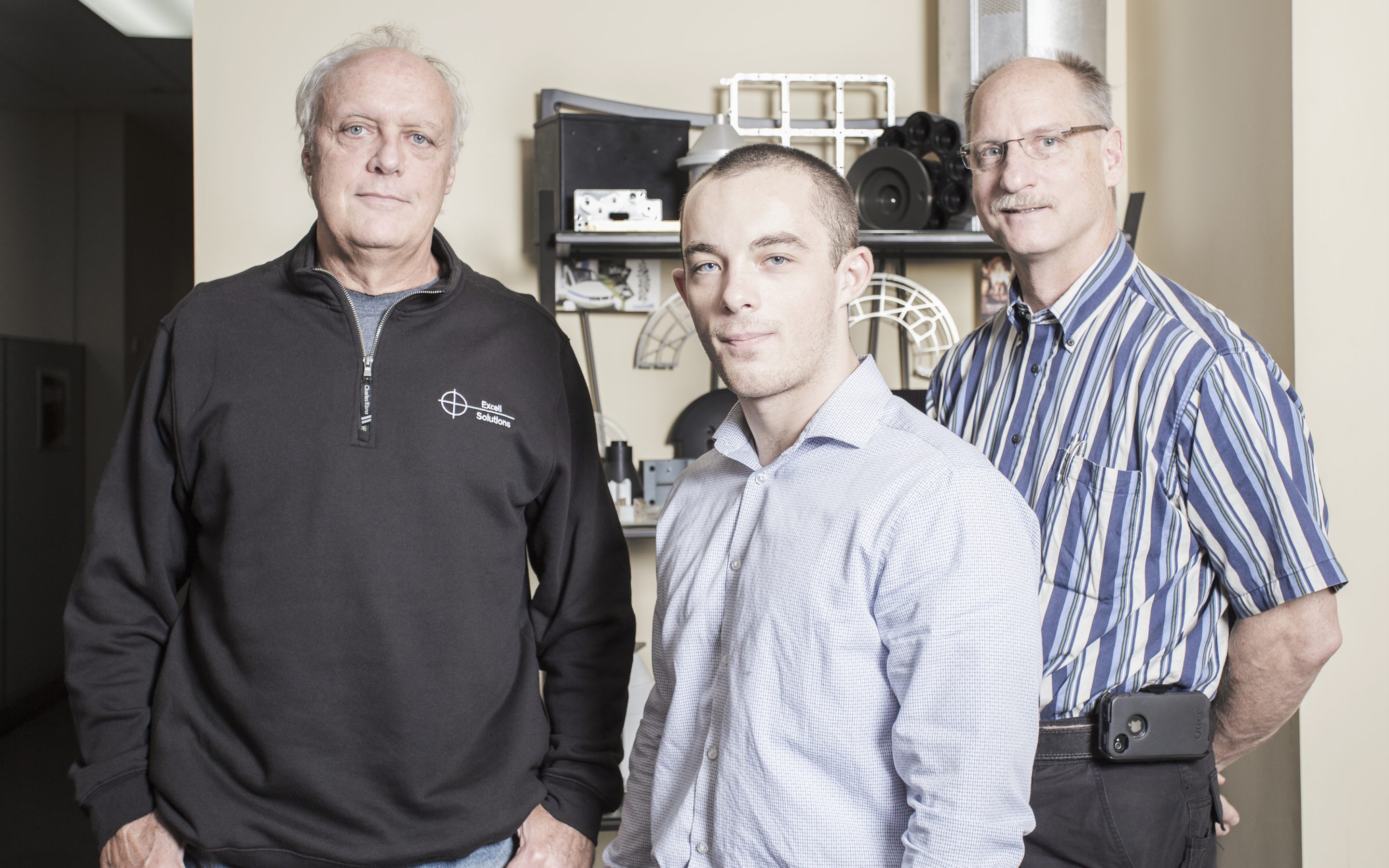

Our Engineering Staff From Left to Right: Tim Dow, Manufacturing Engineer, Jimmy Kendall, Design Engineer and Clay Lennartz, VP of Engineering

There are plenty of reasons for working within close proximity to your customers. Easy accessibility allows for quick, efficient, and effective customer/ vendor interactions. Delivery options become same day and communication/ resolutions become accelerated when you have the convenience of quick in-person meetings. When you work in manufacturing and are dealing with tangible components, these trips become a routine occurrence and allows for speedier interactions and in turn quicker product time to market. In the precision manufacturing space that Excell Solutions has positioned itself, our close proximity to customers also allows for open communication lines when it comes to DFM or Engineering Support.

What is DFM or Engineering support? DFM which stands for design for manufacturing (or manufacturability) is a way for manufacturing companies to work with customers to design a product that not only eases cost but also allows for the manufacturing company to produce parts at a much more rapid pace through the utilization of less resources and cycle times. This usually occurs in the early stages of a project and helps identify areas of challenge that might affect the production build.

After all, who better to help assist in design than the people who will actually be making the parts!?

Here at Excell, our goal is to assist your engineering team and never to replace them. The success of a customer/ vendor DFM project relies heavily on the advice, input, and support of both teams. Don’t worry we will give you all the credit, when it comes to a finished product, leaving your management and accounting teams in AWE!

Meet our engineering team that will be working to assist you in future projects:

Clay Lennartz, VP of Engineering: Clay who acquired his BSME degree from UMass Amherst now has over 30 years of real-world experience in the mechanical engineering space. His knowledge spans well outside the boundaries and capabilities of our shop, making him the perfect person to break down and diagnose areas of concern with all sized projects in any industry.

Jimmy Kendall, Design Engineer: Jimmy received his BSME from UMass Dartmouth in 2017 and will be finishing up his masters degree in Mechanical Engineering at UMass Lowell in the next year. Jimmy has been with the company since 2017 and in that time, there aren’t many things he hasn’t seen, materials he hasn’t dealt with and projects that he hasn’t conquered. As of today, Jimmy is working closely with an autonomous drone company that is working to build a large drone capable of supporting and transporting up to two people.

Tim Dow Manufacturing Engineer: Tim, who also received his degree from the University of Massachusetts (Lowell) and has been with Excell since 2014. Tim has well over 30 years of real-world experience in the field. Tim plays a pivotal role when it comes to breaking down projects and identifying flaws within a design or assembly.

For all inquiries, please contact us using the information below, or visit our website at www.excellsol.com!

Brett Lerner, Sales and Marketing

blerner@excellsol.com

978-663-6100