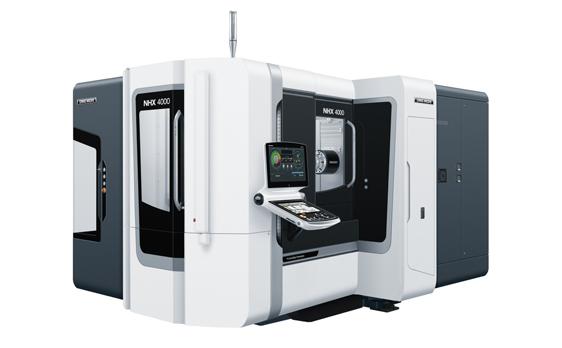

Excell Solutions is excited to introduce our newest piece of precision milling equipment, the DMG Mori HMC NHX 4000. This advanced horizontal machining center is designed to meet the highest standards of precision, reliability, and performance, making it an excellent choice for a wide range of milling applications. As a shop that has always relied heavily on VMC production, it is important for our customers to understand the difference between a VMC and an HMC:

Vertical Milling vs. Horizontal Milling

Vertical Milling:

- Orientation: The spindle axis is vertically oriented.

- Tool Movement: The cutting tool moves up and down along the vertical axis.

- Workpiece Position: The workpiece is typically fixed on a flat table.

- Applications: Ideal for tasks such as drilling holes, cutting slots, and creating flat surfaces.

- Advantages: Easier setup and operation, more accessible for beginners, generally lower cost.

- Limitations: Limited by the vertical axis, less suitable for heavy-duty milling tasks.

Horizontal Milling:

- Orientation: The spindle is horizontally oriented.

- Tool Movement: The cutting tool moves along the workpiece’s surface horizontally.

- Workpiece Position: The workpiece can be mounted on a horizontal table or multiple fixtures.

- Applications: Best suited for heavy-duty tasks, cutting grooves, and large-scale material removal.

- Advantages: Better chip evacuation can handle larger and heavier workpieces, more stable and efficient for heavy cuts.

- Limitations: More complex setup requires more space, generally higher cost.

Benefits of the DMG Mori HMC NHX 4000

High Precision and Performance:

-

- The NHX 4000 is designed for high-precision machining, providing exceptional accuracy and consistency in every cut.

- Advanced thermal control systems reduce thermal displacement, ensuring stable and precise operations

Robust and Reliable:

-

- Built with a sturdy construction, the NHX 4000 offers excellent stability, reducing vibrations and enhancing the precision and quality of the machined parts.

- The machine’s reliability minimizes downtime, enhancing productivity and operational efficiency.

Advanced Technology Integration:

-

- Equipped with the latest control systems, the NHX 4000 offers intuitive and user-friendly interfaces for easier operation.

- It supports advanced automation solutions, allowing for seamless integration into smart manufacturing environments.

Versatility and Flexibility:

-

- The NHX 4000 can handle a wide range of materials and complex geometries, making it suitable for various industries, from automotive to aerospace.

- It offers flexibility in tooling and fixturing, enabling efficient production runs, both small and large.

Cost Efficiency:

-

- The machine’s high-speed capabilities and precision reduce material waste and increase throughput.

- Its energy-efficient design lowers operational costs, contributing to overall cost savings.

To request a quote for the DMG Mori HMC NHX 4000, please contact us using the following information.

Contact Information:

Brett Lerner, Sales

Excell Solutions, Inc

41 Simon St. Nashua, NH 03060

(ph) 603-699-7092 (Main)

(ph) 978-362-0864 (Direct)

(ph) 508-577-1921 (Cell)

We look forward to providing you with a detailed quote and assisting you with any questions you may have about the DMG Mori HMC NHX 4000.