Turning / Turn Mill

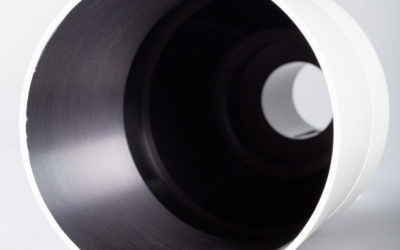

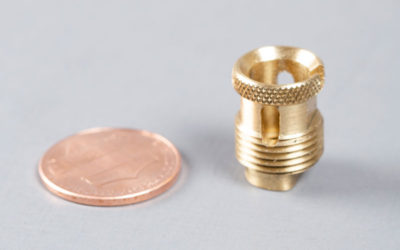

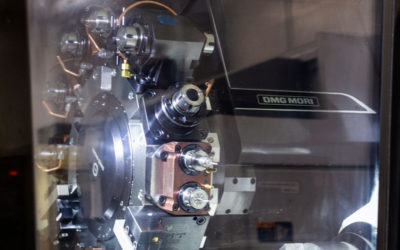

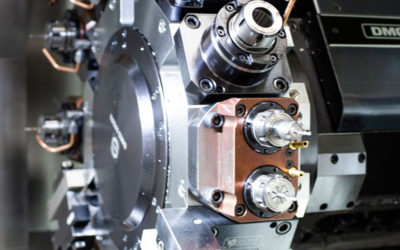

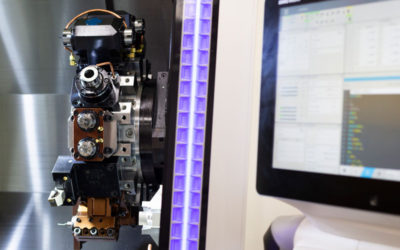

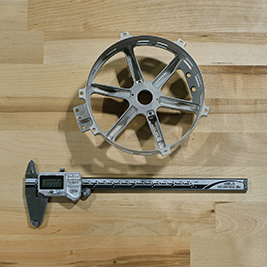

Our customers can design their parts the way they need them to be, with the tolerances and complexity that they truly need. We don’t think a customer should need to alter their design to meet a supplier’s preferences. Excell has invested in several high powered, high precision Mori Seiki and Mazak turn mills to best meet the needs of our customers turned parts. Being able to turn and mill a part in one machine allows them to be made to the highest precision. This also eliminates the need to transfer parts between machines and eliminates the loss of critical tolerances that can accompany a transfer, reducing the risk of error and damage, often reducing lead time needed, and keeping quality to its tightest measurement. You have the freedom to order almost any material in any quantity, even orders as small as quantity 1 with us.

Our customers can design their parts the way they need them to be, with the tolerances and complexity that they truly need. We don’t think a customer should need to alter their design to meet a supplier’s preferences. Excell has invested in several high powered, high precision Mori Seiki and Mazak turn mills to best meet the needs of our customers turned parts. Being able to turn and mill a part in one machine allows them to be made to the highest precision. This also eliminates the need to transfer parts between machines and eliminates the loss of critical tolerances that can accompany a transfer, reducing the risk of error and damage, often reducing lead time needed, and keeping quality to its tightest measurement. You have the freedom to order almost any material in any quantity, even orders as small as quantity 1 with us.  Tungsten and armor to plastic and ceramics, customers don’t need to spend the time on looking, or deal with the stress of keeping track of multiple suppliers. Our uncommonly large range of capabilities allows you to order more of your project together, better assuring quality and part compatibility. We are ITAR registered and ISO certified. Quality is our number one priority.

Tungsten and armor to plastic and ceramics, customers don’t need to spend the time on looking, or deal with the stress of keeping track of multiple suppliers. Our uncommonly large range of capabilities allows you to order more of your project together, better assuring quality and part compatibility. We are ITAR registered and ISO certified. Quality is our number one priority.

We are ITAR registered and ISO certified. Quality is our number one priority.