Water Jet

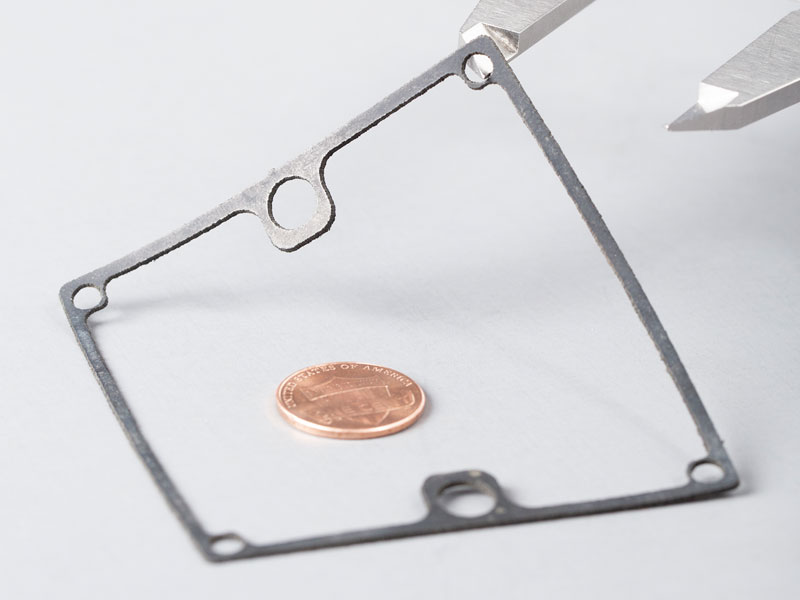

One of the advantages of our large water jet cutter is that it does not involve any heat in the cutting process so it does not create a heat affected zone on metals or add any extra stress to the material. This can have aesthetic, as well as functional, benefits to a part.

For plastics and fibrous materials like glass-reinforced plastics and carbon fiber, waterjet cutting offers clean edges with no delamination, resin melt, or fiber pullout. This often yields a higher quality part than other methods of cutting.

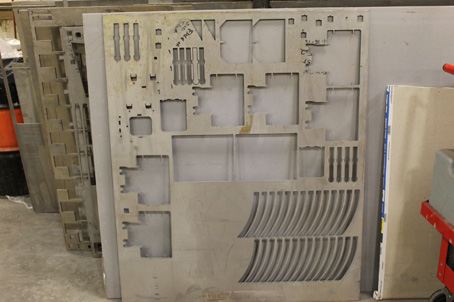

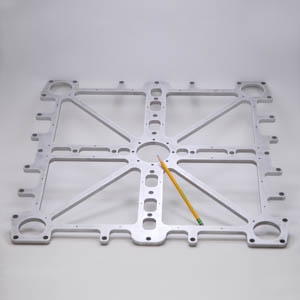

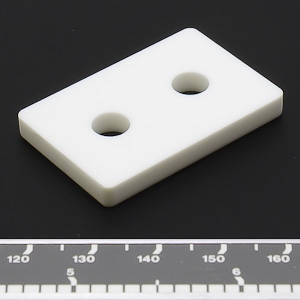

Water is increased to 60,000 PSI, allowing us to cut through materials ranging from ceramic and 1/32” thick rubber, to 6” thick steel. Because of this range of ability, the waterjet allows us to cut a wide variety of materials and shapes in a more cost effective way. When multiple parts are made from the same material, they can be “nested” together from the raw material. This method can further reduce lead time and cost.

We are ITAR registered and ISO certified. Quality is our number one priority.

Brand New WaterJet OMAX 55100

The fastest and most precise abrasive waterjet in the industry!